From the tiniest units of time and matter, a mighty grant for SDSU

The College of Engineering snagged $1.2 million in private funding to explore a potential breakthrough in materials processing.

The W.M. Keck Foundation, which supports high-risk, high-impact research that challenges prevailing paradigms, has awarded a $1.2 million grant to the San Diego State University College of Engineering to test a theory involving the use of nanoseconds-long electronic pulses to develop new advanced materials, beginning with their microstructures.

The three-year grant comes from one of the leaders in private funding for science, engineering and medical research and is a long-sought first for SDSU. Applications to the Keck Foundation are an alternative to more traditional funding mechanisms, including federal sources, where the prospects for a scientific payoff can represent more of a deciding factor.

“It’s a very prestigious grant, and to get it is very difficult,” said Eugene Olevsky, dean of the College of Engineering, Distinguished Professor and one of three principal investigators on the project. “They want to see not incremental progress but something which is a breakthrough within a scientific area, which would present a high potential for opening new areas of research.”

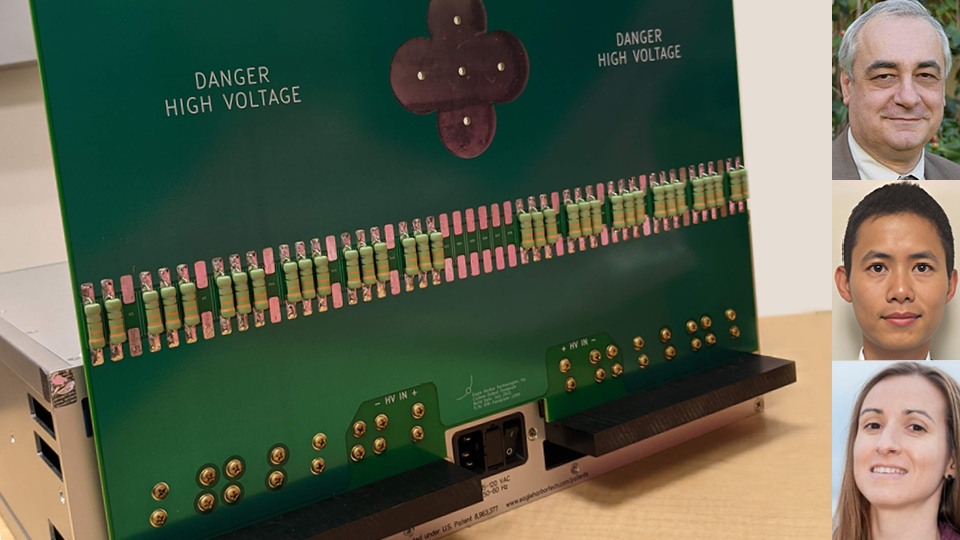

Olevsky’s co-PIs, both from the Department of Mechanical Engineering, are Associate Professor Wenwu Xu and Assistant Professor Elisa Torresani. They began developing the grant proposal in 2024.

If the theory in their proposal proves sound, the researchers said, the ability to improve the strength, resistance to corrosion and other physical properties of materials from the atomic level up could have applications for higher precision in materials processing in aerospace, transportation, manufacturing and other fields.

There’s also a chance the work will confirm the idea doesn’t work, Xu noted — an outcome that would still be an important scientific contribution.

“We are thankful to the Keck Foundation for supporting our researchers to advance world-leading discoveries,” said Hala Madanat, vice president of SDSU’s Division of Research and Innovation. “We have been working toward finding the right fit between the university’s areas of excellence and the Keck Foundation’s priorities for several years, so it is very exciting to have secured our first grant from them so soon after being officially recognized as an R1 institution.”

SDSU achieved R1 status from the Carnegie Classification of Institutions of Higher Education in February, recognizing universities with “Very High Research Spending and Doctoral Production.”

A committee assembled by SDSU’s Division for Research and Innovation (DRI) selected the College of Engineering proposal from several concepts across campus. Proposals from SDSU to the foundation date back to at least 2014, records show.

Xu said a one-page abstract was sent to the foundation in November 2024, competing with other universities for funding. It was accepted in February 2025 and Keck sent a delegation for a half-day, onsite visit the next month, meeting with the principal investigators, university leadership, postdoctoral and student researchers and others involved in the work. The proposal also was submitted to multiple external experts for review.

Word of the foundation’s approval came through in June.

SDSU’s advantages, Xu said, may have included the fact the Keck delegation included a scientist with 20 years of experience in the field of materials research. “He saw the innovative aspect of our proposal,” Xu said. “He liked it.”

Energy pulses

Like repurposing a smartphone as a security camera, the SDSU adapted a device designed to test electronic equipment, using it to discharge pulses of energy in nanoseconds as part of the heating process in materials processing.

These pulses would be used to alter the structures and properties of materials at the atomic level. If the theoretical aspects of the project prove to be valid, Olevsky said, it could become a tool in making stronger metals or ceramics possessing also a wide range of unique functional properties.

The project is called “New Materials Processing via Electro-Nano-Pulsing,” and it doesn’t get much simpler from there but here are the basics.

In the building blocks of matter, “grains” are regions within a solid, crystalline material where the atoms are arranged in a consistent, three-dimensional repeating pattern. Each grain is a single crystal, and these crystals are tightly packed together within the material. The grains touch at the “grain boundary,” where the atomic arrangement changes. Grains and the grain boundaries are at the core of the work at SDSU.

Traditionally, in materials processing, you need heat and pressure. This could be done in a furnace or pressing device, using, for example, hot stamping to create a sword.

One of the heat application methods is Joule heating, or resistance heating, which relies on an electric current to produce the heat. Electrons carry the current and collide with atoms in the conductor, causing them to vibrate more rapidly and increasing the material's temperature. The properties of the material are affected by the amount of heat and pressure applied and, potentially, by the electric current itself.

This is called field-assisted processing due to the involvement of an electromagnetic field. When you heat a burrito or cup of coffee at home in the microwave, the pulsed waves generated in the oven are a type of field-assisted processing.

Controlling the orientation, structure and composition of grain boundaries through resistance heating can influence the properties of the material, including its strength, ductility, and resistance to corrosion. But electric currents affect grains and grain boundaries in different ways because grain boundaries have a higher resistance.

“And because of that there is an idea that maybe if you pass this electric current, then due to higher resistance this boundary between grains will be heated more,” Olevsky said. “Then at a certain point, due to their structure transformations, these grain boundaries will become harder than grains.”

Looking ahead

The ability to control the structure of grain boundaries independently from the structure of grains ― having the grain boundaries (which are responsible for materials strength) reach their melting point while the grains (responsible for materials ductility) are still solid ― would be a very valuable tool for materials processing. An armor that is both ductile and strong, able to repel a bullet by absorbing its kinetic energy without total fracture, for example, would be quite an achievement.

Electrical current can be constant or delivered in pulses, and the SDSU team proposes to study the delivery of the current in powerful nano-pulses, billionths of a second in duration. At an early stage of work on the idea Xu identified a company in Seattle, Eagle Harbor Technologies, marketing an Integrated Power Module device that delivers nano-pulses to test electronics circuitry.

The device had no direct connection to materials processing but the SDSU team purchased a prototype and modified it.

“We tested it, then we had some aha moment when our eyes popped,” Olevsky said. Their observations, he said, showed electro-nano-pulsing could be “a transformative tool for unique materials design.”

Xu said the Keck grant will allow the team to obtain a version of the device about four times more powerful in its current pulsing for further testing.

About the W. M. Keck Foundation

The W. M. Keck Foundation was established in 1954 in Los Angeles by William Myron Keck, founder of The Superior Oil Company. One of the nation’s largest philanthropic organizations, the W. M. Keck Foundation supports outstanding science, engineering and medical research. The Foundation also supports undergraduate education and maintains a program within Southern California to support arts and culture, education, health and community service projects.